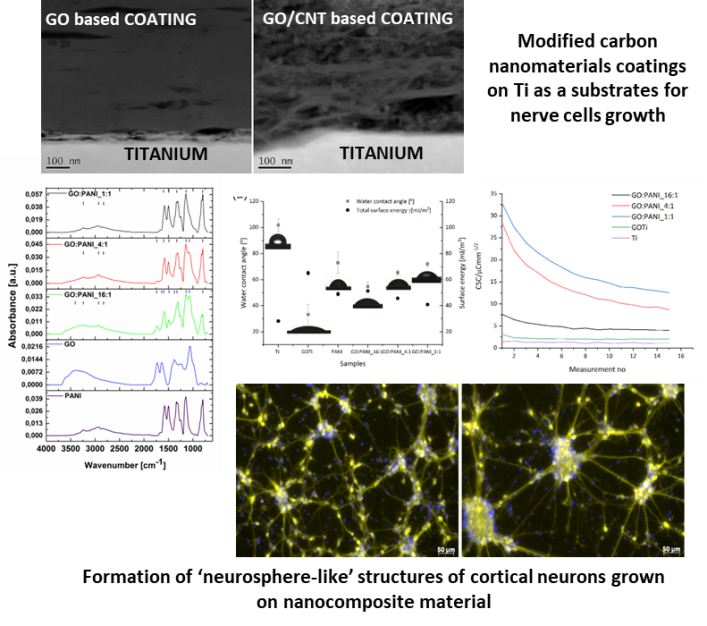

Carbon nanomaterials, such as carbon nanotubes (CNTs), graphene, graphene oxide (GO) and nanocomposites based on them, are gaining more and more interest in the regeneration of nervous tissue. They are highly advantageous due to their appropriate microstructure, excellent conductive and biomimetic properties as well as vast possibilities of physicochemical properties modifications. Therefore, the carbon nanomaterials and nanocomposites based on nanocarbon and conductive polymers coatings obtained on the surface of metallic substrates via EPD (electrophoretic deposition method) are an interesting alternative to the platinum or steel electrodes used for stimulating the central nervous system (CNS) cells. The GO significantly improves viability of human neuroblastoma SH-SY5Y cells in comparison with CNTs. The appropriate amount of polyaniline (PANI) efficiently increases viability and neurite outgrowth in contact with both SH-SY5Y cells and primary neurons, even compared with the pure GO coating (Fig.1)[1,2]. Such a sample also proved to accelerate the process of 3D structures creating and maturing under the standard 2D cell culture conditions - observed as ‘neurosphere-like’ structures of cortical neurons in photomicrographs (Fig.1) [2]. Thus, thanks to its appropriate physicochemical properties (surface charge, appropriate contact angle, electrical conductivity and morphology), the material may serve as an intelligent substrate stimulating the reproduction of nervous tissue structures present in the CNS.

[1] A. Frączek-Szczypta, D. Jantas, F. Ciepiela, J. Grzonka, A. Bernasik, M. Marzec. Carbon nanomaterials coatings - properties and influence on nerve cells response. Diamond and Related Materials 84 (2018) 127–140.

[2] A. Frączek-Szczypta, D. Jantas, F. Ciepiela, J. Grzonka. Graphene oxide-conductive polymer nanocomposite coatings obtained by the EPD method as substrates for neurite outgrowth. Diamond and Related Materials 102 (2020) 1–15.

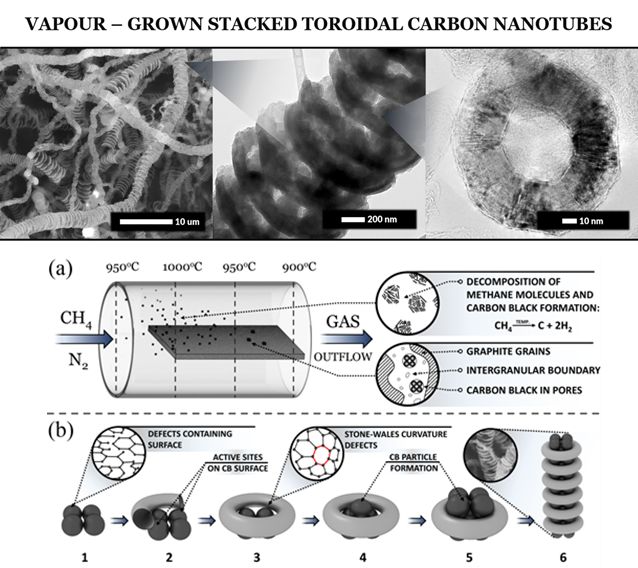

Another research area is the synthesis of novel carbon nanostructures, such as stacked toroidal carbon nanotubes (STCNTs), and the use of new catalysts, e.g. montmorillonite (MMT), for the synthesis of carbon nanoforms. The new carbon nanostructure - STCNTs - was crystallized from the gas phase through the catalyst-free deposition process. The vapor-grown STCNTs were obtained on a graphite substrate using methane as a source of carbon. TEM images revealed that the nanostructured carbon phase consisted of a single toroidal element (toroid) composed of rolled multi-walled carbon nanotubes (Fig.2) [3]. MMT acted as a catalyst for the CNTs growth via the gas phase at 1000 °C. The CNTs growth in the pitch-derived carbon material resulted from the presence of hydrocarbon compounds containing PAH (evolved during the thermal conversion to the carbon phase). The catalytic growth of CNTs from aromatic hydrocarbons containing the gaseous phase allows to reduce the PAH emission during the pitch-derived carbon thermal processing [4]. This simple method of pitches modification with ceramic nanofillers can be an interesting solution, significant for environmental reasons and in compliance with the European Union regulation i.e. REACH.

[4] M. Gubernat, A. Frączek-Szczypta, J. Tomala, S. Błażewicz. Catalytic effect of montmorillonite nanoparticles on thermal decomposition of coal tar pitch to carbon. Journal of Analytical and Applied Pyrolysis 130 (2018) 90–98.

[3] M. Gubernat, M. Zambrzycki, A. Frączek-Szczypta, S. Błażewicz. Structural and microstructural study of novel stacked toroidal carbon nanotubes. Micron 130 (2020) 1–9.

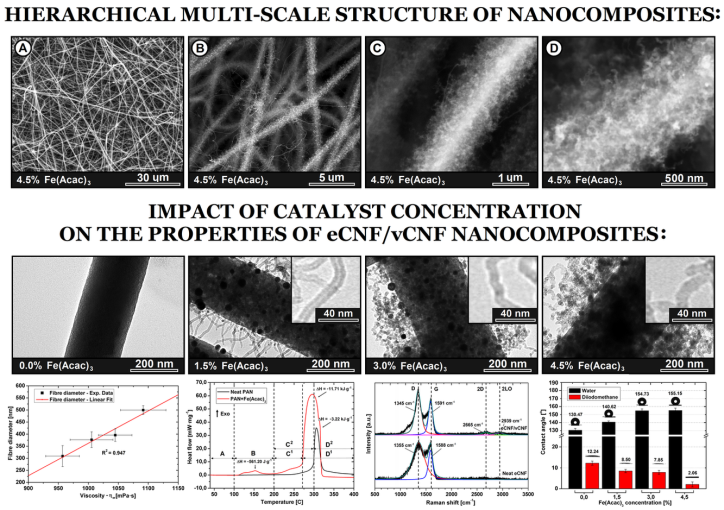

In recent years, extensive research on miscellaneous structures of nanocarbons has created a novel class of materials, known as hierarchical carbon nanocomposites. A flagship example are hierarchically structured carbon nanofibres, also known as branched nanofibres. On the nanometric scale, in their structure one can distinguish the core carbon nanofibres (CNFs) from which much smaller fibrous nanoprotrusions (e.g. carbon nanotubes - CNTs) stick out perpendicularly to the main axis of the core nanofibres (Fig.3). Such a type of hierarchical ordering leads to the significantly enhanced specific surface area, high density of catalytically and adsorption active sites, improved electrical conductivity, better mechanical stability and sensing capabilities, etc. Therefore, the hierarchical structure of CNs widens their applicability, especially in the fields of energy conversion and storage, catalysis, nanoelectronics, sensors, biomaterials and filtration. The research group attempted to obtain hierarchical nanocomposites using acetylacetonate (Acac) as a catalyst for the growth of CNTs on the CNF surface [5]. Numerous tests were performed to optimize the conditions of the fiber formation via electrospinning and the conversion of these materials to carbon, as well as to optimize the conditions of CNTs synthesis via the CVD method. The obtained results concerning their structure, microstructure, and electrical and electrochemical properties are very promising, therefore the research will continue, especially to develop elements for constructing the dye-sensitized solar cell (DSSC) [5,6].

[5] M. Zabrzycki, A. Frączek-Szczypta. Study on the synthesis and properties of hierarchically structured electrospun/vapour-grown carbon nanofibres nanocomposites. Journal of Industrial and Engineering Chemistry 86 (2020) 100–112.

[6] M. Zambrzycki, S. Łoś, A. Frączek-Szczypta. Structure and electrical transport properties of carbon nanofibres/carbon nanotubes 3D hierarchical nanocomposites: Impact of the concentration of acetylacetonate catalyst. Journal of the European Ceramic Society 2020. In press.

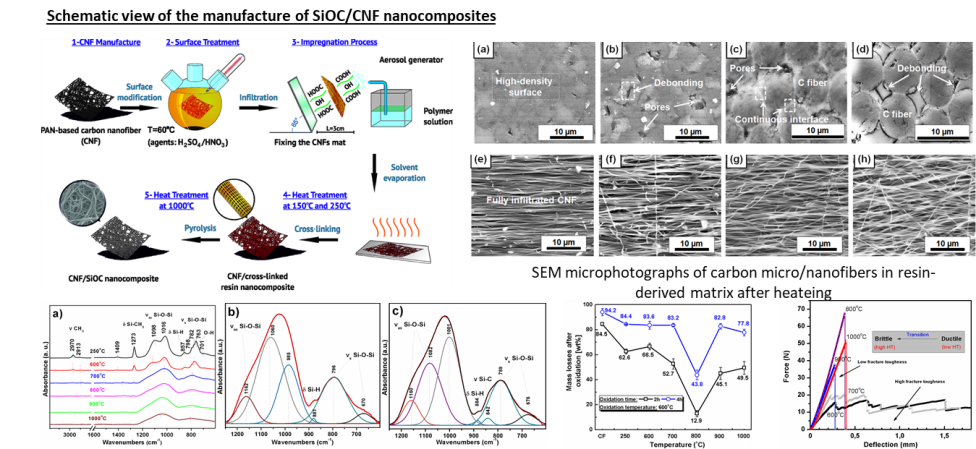

Another area of our research are ceramic nanocomposites modified with nano- and microfibers where the ceramic phase resulted from the thermal transformation of silicon-containing polymer (Fig.4). The polysiloxane-derived ceramic matrix composites and nanocomposites (CMCs or CMNCs) with carbon phases are an interesting path of developing materials applicable in modern electronics as multifunctional nanocomposites, electrochemical power sources for next generation of Li-ion batteries, flexible electrodes, fuel cells and supercapacitors. The presence of the ceramic phase in composites/nanocomposites with carbon nanofibers increases the advantageous oxidation resistance and improves their mechanical properties in comparison to polymer composites/nanocomposites. In the case of CMCs or CMNCs the key is to achieve an optimal bond between components. In the PMC technique and preceramics-based CMCs the most important challenge is to control the complex chemical and physical reactions during heat treatment that cause shrinkage, the pore generation and the formation of stresses at the fiber/matrix interface. The literature still lacks systematic studies on the interaction of carbon micro/nanofiber with polysiloxane matrix, the effect of CF/CNF on decomposition mechanism of polysiloxane resins and their interaction with ceramic matrix as well as the functional properties of obtained ceramic/carbon composites. Therefore, further research on this behaviour is crucial for developing novel high-performance CMNCs with the controlled thermo-mechanical characteristics [7,8].

[7] K. Sokołowski, P. Pałka, S. Błażewicz, A. Frączek-Szczypta. Carbon nanofibers-based nanocomposites with silicon oxy-carbide matrix. Ceramics International 46 (2020) 1040–1051.

[8] K. Sokołowski, M. Gubernat, S. Błażewicz, A. Frączek-Szczypta. Comparative study of interphase evolution in polysiloxane resin-derived matrix containing carbon micro and nanofibers during thermal treatment. Journal of the European Ceramic Society 40 (2020) 5205-5216.