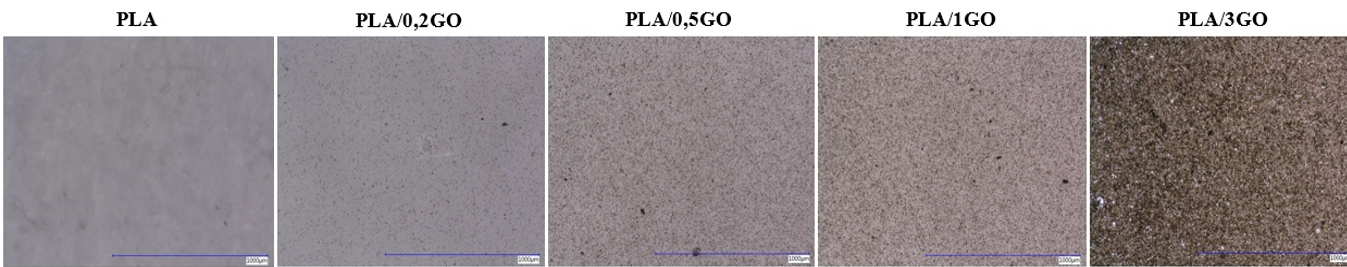

The modification of the metal implants surface in order to change its morphology and properties is one of the most current issues in the research concerning these biomaterials. Obtaining a nanostructure of the implant surface, e.g. via the chemical treatment, makes it possible to improve the cell adhesion and to promote a better connection of the implant surface with the applied coating. Multifunctional coatings with bioactive and antibacterial properties may improve the biological response to the metal implant introduced into the organism. The polymer coatings of polyurethane or polylactide, modified with bioactive additives of TCP or HAp particles and antibacterial additives of nanometric size (nanosilver, graphene and graphene oxide - nAg, G, GO) are an interesting proposition to endow implants with novel advantages. The use of available and inexpensive methods, such as the dip coating method or electrophoretic deposition of EPD, results in obtaining continuous nano- or micrometric coatings of good quality and efficient adhesion to the substrate.

[1] Szaraniec B., Pielichowska K., Pac E., Menaszek E. (2018) Multifunctional polymer coatings for titanium implants. Materials Science and Engineering: C, 93: p. 950-957

[2] Pokrowiecki R., Zaręba T., Szaraniec B., Pałka K., Mielczarek A., Menaszek E., Tyski S., (2017) In vitro studies of nanosilver-doped titanium implants for oral and maxillofacial surgery. Int J Nanomedicine, 12: p. 4285-4297

[3] Morawska-Chochół A., Domalik-Pyzik P., Szaraniec B., Chłopek J., (2016) The effect of magnesium alloy wires and tricalcium phosphate particles on apatite mineralization on polylactide-based composites. Materials Letters, 180: p. 1-5.

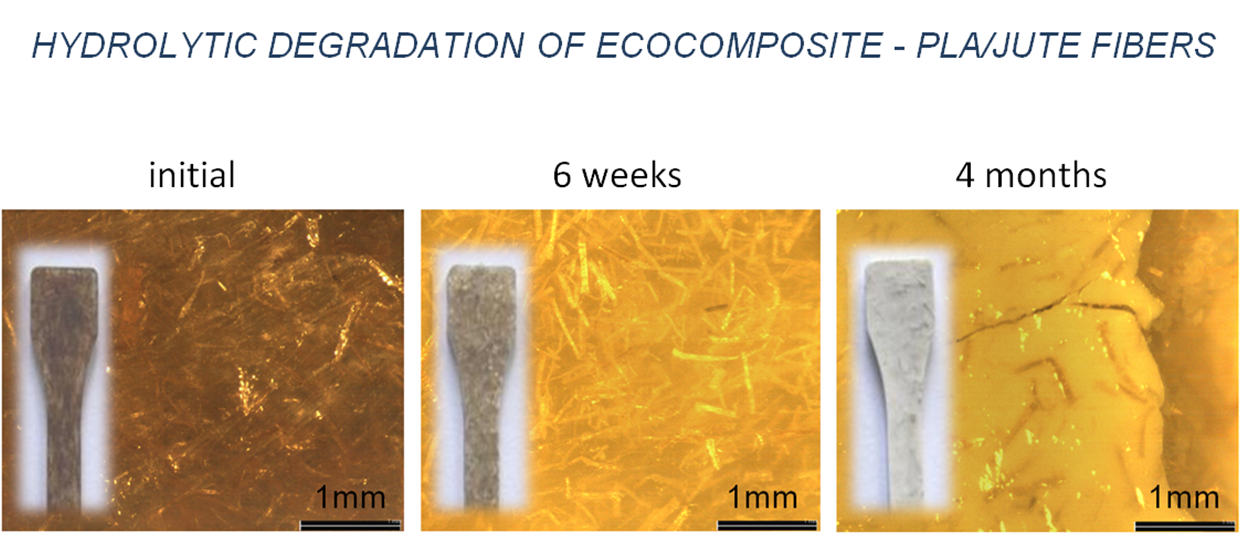

Nowadays, a particularly pressing problem concerning packaging and disposable products is their negative impact on the environment. Threfore, finding a solution based on environmentally friendly raw materials and products is a key research direction in modern materials engineering. The use of renewable raw materials and/or biodegradable materials will significantly reduce the amount of polymer/plastic waste. Degradable materials in the form of films and shapes that will contribute to the environmentally-friendly production, are being researched: polylactide (PLA), its copolymers and blends with other polymers; polyhydroxybutyrate (PHB); thermoplastic starch (TPS); cellulose; chitosan; collagen; alginates. Depending on the structure and composition, it is possible to manufacture products with "tailored" time and method of degradation (from several days to several years). Since degradable plastics are more expensive than the traditional ones (such as polyethylene (PE), polypropylene (PP), polystyrene (PS)), one method to reduce the cost may be introducing a cheaper but also biodegradable filler into the polymer matrix, e.g. wood flour, wood shavings, nut shells, mineral powders or starch. Besides the cost reduction, such a solution offers a possibility of unconventional design and endowing the material with new features (e.g. barrier). Additionally, processing of these degradable thermoplastics takes place on standard devices used for plastics processing, i.e. extruder, injection molding machine.

[4] Szaraniec B., Morawska-Chochół A. (2012) Ocena trwałości w środowisku naturalnym W: Biokompozyty z surowców odnawialnych: praca zbiorowa pod red. S. Kuciela i H. Rydarowskiego, Kraków: Politechnika Krakowska. ISBN: 978-83-7242-639-0