Energy efficiency in complex systems (EECS)

AGH University of Science and Technology

Faculty of Energy and Fuels

Department of Thermal and Fluid Flow Machines

Jacek Leszczynski is a Full Professor at AGH University of Technology, Faculty of Energy and Fuels, Department of Thermal and Fluid Flow Machinery, Cracow, Poland. He worked over twenty five years in project grants, industrial applications and academic programs that concern the following main scientific activities like modelling of complex systems and energy efficiency. He has been Principal Investigator and Research Coordinator on applied research and development projects at around 35 M€ including three successful EU project grants. His scientific activity includes modelling techniques of complex systems involving compressed air systems, energy efficiency, energy harvesting systems and devices, mechanics/flows of granular materials, fractional derivatives, population balance and DEM techniques, soft magnetic materials and inductive elements operating in high frequency bandwidth, as well as management of R&D groups oriented industrially. Summarizing educational background, he supervised many MSc theses from Energy Engineering, Computational Science, Mathematics and Environmental Protection and two PhD theses from Mechanical Engineering. He is an active member and expert of many scientific organizations, like National Centre of Research and Development, IEEE and the EU. He acts as Subject Editor of Applied Mathematical Modelling Journal (USA).

Members

Dominik Gryboś is an assistance at AGH University of Technology, Faculty of Energy and Fuels, Department of Thermal and Fluid Flow Machinery. His scientific activity includes energy efficiency in inudstrial pneumatic systems, waste energy recovery systems, energy storage in compressed air and methods of purifying polluted air.

Research topics

Energy efficiency of complex systems

Assessment of energy efficiency of industrial systems, studies of autonomous energy systems.

Waste energy recovery systems and technologies on a fractional industrial and industrial scale

Design and development of technologies for the recovery, storage and processing of waste energy in order to increase the energy efficiency of machines and devices. Research on waste air energy management technology.

Research on processes and phenomena related to granular matter in the aspects of energy, environmental engineering, mining, mechanical engineering

Research in the field of mathematical description of complex systems and phenomena using the calculus of non-integer-order operators along with engineering applications in power industry, engineering and environmental protection, mechanical engineering. Elaboration and development of technologies for the reduction of airborne dust in urbanized areas in the aspect of controlling the pollution of solid particles on a large scale

Publications

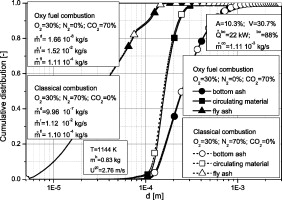

Leszczyński J.S.

Basic boiler cumulative distributions (fly ash, circulating material, bottom ash) — oxy-fuel and classical combustion conditions

Powder Technology 249, 2013, 536-548

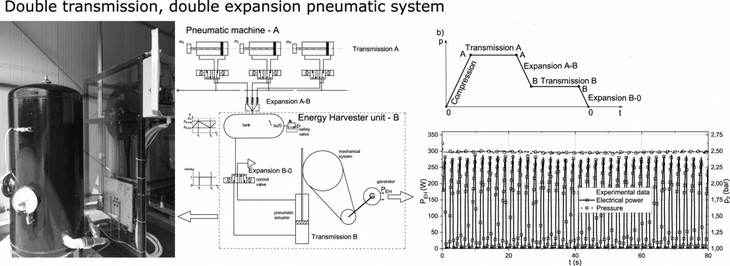

Leszczyński J.S., Gryboś D

Compensation for the complexity and over-scaling in industrial pneumatic systems by the accumulation and reuse of exhaust air

Applied Energy 39, 2019, 1130-1141

Grybos D., Leszczynski J.S., Czopek D. and Wiciak J., „Exhaust noise reduction by application of expanded collecting system in pneumatic tools and machines”, Energies. 2021; 14(6):1592. https://doi.org/10.3390/en14061592

D. Gryboś, J. S. Leszczyński, “Double transmission double expansion technology as a method for reducing energy losses associated with oversizing of industrial compressed air systems”, eceee Industrial Summer Study proceedings 2020, vol. 4, 14–17 September 2020, Online. https://www.eceee.org/library/conference_proceedings/eceee_Industrial_Summer_Study/2020/4-technology-products-and-systems/double-transmission-double-expansion-technology-as-a-method-for-reducing-energy-losses-associated-with-oversizing-of-industrial-compressed-air-systems/

Leszczynski J. S. and Grybos D., „ Sensitivity analysis of Double Transmission Double Expansion (DTDE) systems for assessment of the environmental impact of recovering energy waste in exhaust air from compressed air systems”, Appl. Energy, t. 278, 115696, 2020. https://doi.org/10.1016/j.apenergy.2020.115696

Swieboda C., Walak J., Soinski M., Rygal J., Leszczynski J. and Grybos D., „Nanocrystalline oval cut cores for current instrument transformer prototypes”, Measurement, t. 136, ss. 50–58, mar. 2019. https://doi.org/10.1016/j.measurement.2018.12.064

Grybos D., Leszczynski J. S. „ Implementation of Energy Harvesting System of Wastes of Compressed Air Wastes for Electrical Steel Cutting Line”, w E3S Web of Conferences, 2019, t. 108, nr 01005, ss. 1–8. https://doi.org/10.1051/e3sconf/201910801005

Gryboś D., Leszczyński J.S., Kwiecień M., Świeboda C., Lasak P., Pluta. W, Rygał R., Soiński M. „Properties of Fe-based nanocrystalline magnetic powder cores (MPC) and structure of particle size distribution (PSD)”, J. Electr. Eng., t. 69, nr 2, ss. 163–169, 2018. https://doi.org/10.2478/jee-2018–0020

Gryboś D., Leszczyński J.S., Świeboda C., Pluta W., Kwiecień M., Rygał R., Soiński M. „Magnetic properties of composite cores made of nanocrystalline material for high requency inductors and transformers”, 2018 Innov. Mater. Technol. Electr. Eng. i-MITEL 2018, ss. 1–6, 2018. https://doi.org/10.1109/IMITEL.2018.837046

Leszczyński J.S., Błaszczak M.Modeling the transition between stable and unstable operation while emptying a siloGranular Matter 13(4), 2011, 429-438. https://doi.org/10.1007/s10035-010-0240-5

Other publications: https://bpp.agh.edu.pl/autor/leszczynski-jacek-20006

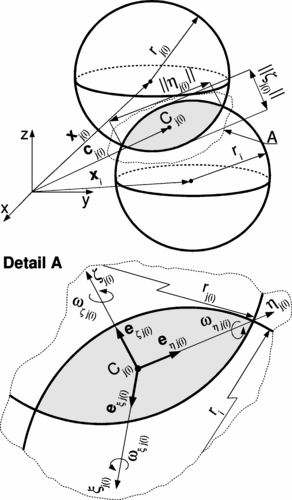

Leszczyński J.S.

Using the fractional interaction law to model the impact dynamics of multiparticle collisions in arbitrary form

Physical Review E 70, 2004, 051315

Patents

Nanocrystalline magnetic powder cores

J.S. Leszczynski, M. Soinski, R. Rygał, D. Gryboś, i in., Sposób wytwarzania rdzenia magnetycznego ze sproszkowanego materiału nanokrystalicznego”. Polish Patent Office, Patent PL228991B1, Warsaw, 2018.

Double transmission double expansion technology

Leszczyński J., Burchan A., Chalusiak M., Grzegorzak M., Jerominek T., Kamiński R., Kastelik K., Plewa A., Polak K., Surowiec M., Tomasik B., Walczak K. „Device for transformation of pulse gravity energy to electric energy” Polish Patent Office, Patent PL228304B1, Warszawa, 2017.

Leszczynski J.S., Gryboś D., „ The method and device for converting waste energy of compressed gas into electricity”., Polish Patent Office, Patent pending PL22009A1, Warszawa, 2018.

Leszczynski J. S., Gryboś D., Machulec D. System and method for recovery of compressed gas waste energy, Polish Patent Office, Patent pending PL426071A1, Warsaw, 2019.

Leszczynski J.S., Gryboś D., Bolek M. Układ do kolektorowania powietrza odpadowego z sekcji instalacji pneumatycznej, Polish Patent Office, Patent pending PL432516A1, Warsaw, 2020.

Method of purifying polluted air in the region of an inversion layer

Leszczynski J. S., Kubica B., Suwała W., Stobiński M, Zyśk J., Jędrzejek F., Gryboś D., Bolek M. Sposób obniżenia stężenia pyłów w warstwie smogu, stanowiącej warstwę inwersyjną, Polish Patent Office, Patent pending PL434933A1, Warsaw, 2020.

Leszczynski J. S., Kubica B., Suwała W., Stobiński M, Zyśk J., Jędrzejek F., Gryboś D., Bolek M. Method of purifying polluted air in the region of an inversion layer, European Patent Office, Patent pending Ep20217680, Munich, 2020.

Projects

Projektu „Inkubator Innowacyjności 2.0”,

WPP/2.0/07/2019, VI 2019- III 2020,

Prace przedwdrożeniowe projektu „Rozwój technologii podwójnego przesyłu i podwójnego rozprężania do magazynowania i ponownego wykorzystania energii odpadowej powietrza sprężonego”

Projektu „Inkubator Innowacyjności 4.0”,

WPP/4.0/9/2021, I 2021- IV 2022

Prace przedwdrożeniowe projektu „Opracowanie systemu interwencyjnej redukcji stężenia pyłów zawieszonych w powietrzu”

Projekt Programu Inteligentny Rozwój 2014-2020

Magneto Sp. z o.o.

POIR.01.01.01-00-0306/15, 2016-2018,

Badania przemysłowe nowego typu rdzeni magnetycznych wykonywanych z taśm amorficznych, nanokrystalicznych, cienkich blach elektrotechnicznych i materiałów kompozytowych pracujących w podwyższonych częstotliwościach