|

Home |

Niekonwencjonalne

technologie i procesy przeróbki plastycznej

Procesy wyciskania i kucia z udziałem fazy

ciekłej

What is Thixoforming? The

University of Sheffield Technology Transfer Centre:

What is Thixoforming? The

University of Sheffield Technology Transfer Centre:

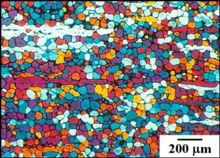

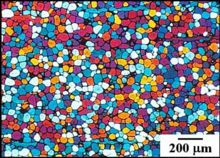

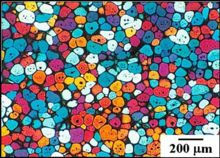

A spheroidal microstucture suitable for thixoforming; A conventional dendritic microstructure

University of Sheffield: 1), 2), 3), 4), 5),

6), 7) >

University of Sheffield: 1), 2), 3), 4), 5),

6), 7) >

![]() 1)

Feedstock Routes; Rap

and Sima Routes Depending on Deformation and Recrystallation

1)

Feedstock Routes; Rap

and Sima Routes Depending on Deformation and Recrystallation

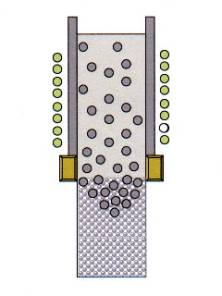

^ Magnetohydrodynamic

Stirring (MHD)

![]() 2) Development of

Hypereutectic Aluminium Alloys for Thixoforming based on the A390 composition

2) Development of

Hypereutectic Aluminium Alloys for Thixoforming based on the A390 composition

|

Mechanical properties of thixoformed

A390 alloys |

|||||

|

As thixoformed |

|||||

|

Alloy |

E (GPa) |

Y.S. R0.2

(MPa) |

UTS Rm

(MPa) |

Elong. A5

(%) |

Hardness (HRB) |

|

477 |

78 |

215 |

271 |

1.04 |

67 |

|

500 |

76 |

225 |

277 |

0.72 |

71 |

|

501 |

91 |

252 |

261 |

0.3 |

76 |

|

T6 |

|||||

|

477 |

78 |

NA |

429 |

0.16 |

84 |

|

500 |

82 |

NA |

411 |

0.10 |

84 |

|

501 |

94 |

348 |

354 |

0.25 |

83 |

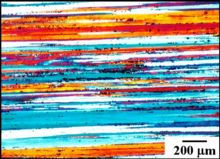

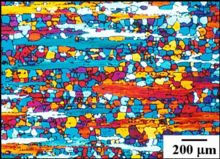

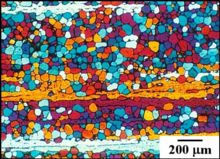

Microstructure of alloy 477: as received and as thixoformed (x100):

Automotive

Component (Brake Drum); An

automotive part (brake drum) was thixoformed by Stampal S.p.A. ^

using the A390 standard alloy. The part shown below is in the T6 heat treated

condition, weighs 1.7 kg, and is substituting a cast iron part. The part offers

lower weight and good wear resistance.

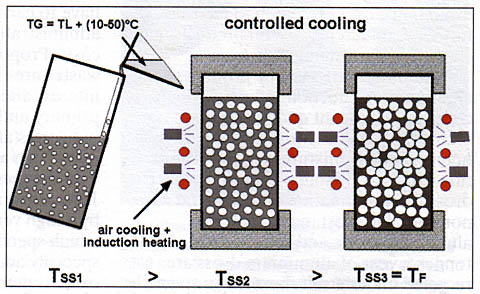

![]() 3) Microstructural Development

3) Microstructural Development

Microstructural development in slugs cut out from extruded bar of 7075 wrought aluminium alloy (longitudinal cross section), heated isothermally at different

temperatures and holding times (in

brackets). (e) represents good thixoformable

microstructure:

|

|

|

|

|

a) 465°C (1.5

min) |

b) 575°C (1.5

min) |

c) 610°C (2

min) |

|

|

|

|

|

d) 615°C (2

min) |

e) 620°C (2

min |

f) 625°C (2

min) |

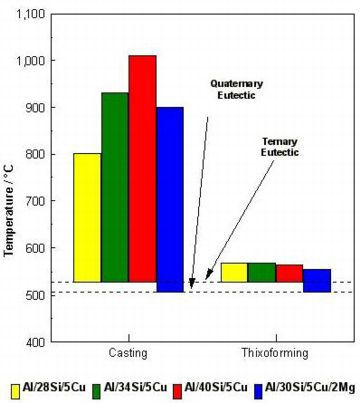

![]() 4)

Novel Metal

Matrix Composites Based on Hypereutectic Aluminium/Silicon Alloys

4)

Novel Metal

Matrix Composites Based on Hypereutectic Aluminium/Silicon Alloys

|

Comparison of Forming Temperatures and Solidification Ranges of Al/Si

Alloys in Thixoforming and Casting

|

Strength, Youngâs Moduli and Shear Moduli of Thixoformed Al-Si-Cu

Alloys

#

Supplied by Showa in Japan |

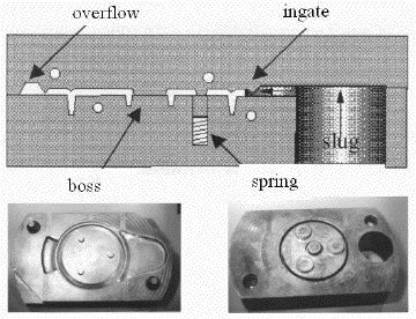

![]() 5) Thixoforming Of An

Electric Motor Endplate

5) Thixoforming Of An

Electric Motor Endplate

Die Used For Thixoforming Electric Motor

Endplate:

6a) Description of Press

6a) Description of Press  6b) Thixoforming of

copper electric motor rotors

6b) Thixoforming of

copper electric motor rotors

Thixoformed rotor with copper squirrel

cage ^

The rotor is about 75 mm diameter

and 75 mm high. It consists of a stack of 40 soft iron laminations held together by the copper conductor, which is thixoformed through the

stack.

![]() 7) Thixoforming of High

Temperature Alloys

7) Thixoforming of High

Temperature Alloys

Injection of hot billet ^ Tool steel part after injection ^ Thixoformed M2 tool steel and

stellite ^

![]() Publikationen (różne publikacje w PDF):

Publikationen (różne publikacje w PDF):

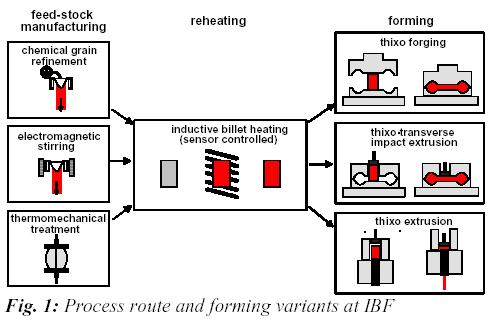

![]() Thixoforging

of aluminium alloys with a hydraulic forging press (pdf)

Thixoforging

of aluminium alloys with a hydraulic forging press (pdf)

![]() THIXOFORGING

AND THIXOEXTRUSION - BENEFITS

THIXOFORGING

AND THIXOEXTRUSION - BENEFITS

OF INNOVATIVE FORMING TECHNOLOGIES (pdf)

![]() Untersuchungen

zum Thixoforming von Stahlwerkstoffen

Untersuchungen

zum Thixoforming von Stahlwerkstoffen

^Induktive Erwärmung eines Stahlrohlings in den

thixotropen Bereich ^Auswahl am IFUM thixogeschmiedeter Stahlbauteile

Zbiory

ogólne:

![]() Słownik – Glossary - AEC

Słownik – Glossary - AEC

![]()

|

Home |

Aktualizowano:

2003-03-25