|

Home |

Walcownictwo

<

<![]()

![]() HUTA

METALI NIEŻELAZNYCH "SZOPIENICE" S.A.

HUTA

METALI NIEŻELAZNYCH "SZOPIENICE" S.A.

|

|

Wyroby z miedzi i mosiądzu : |

|

![]() Walcownia Metali Nieżelaznych

WMN Sp. z o.o (Gliwice – Łabędy)

Walcownia Metali Nieżelaznych

WMN Sp. z o.o (Gliwice – Łabędy)

![]()

![]() Strip Casting Machines,

Strip Casting Machines,

![]() Aluminum Strip Casting Machines,

Aluminum Strip Casting Machines,

![]() Copper Strip Casting Machines,

Copper Strip Casting Machines,

![]() Zinc & Lead Strip Casting

Machines,

Zinc & Lead Strip Casting

Machines, ![]() In-Line Processing

In-Line Processing

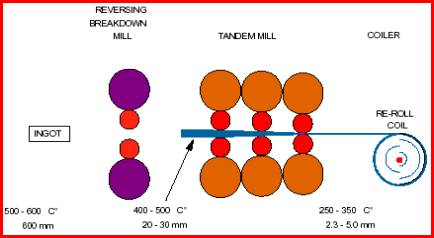

Figure : Hot-rolling principle

The DC ingot is usually

cooled after casting to room temperature and then re-heated to around 500°C

prior to successive passes through a hot rolling

mill where it is reduced in thickness to about 5 - 8 mm (see Figure).

The DC ingot is usually

cooled after casting to room temperature and then re-heated to around 500°C

prior to successive passes through a hot rolling

mill where it is reduced in thickness to about 5 - 8 mm (see Figure).

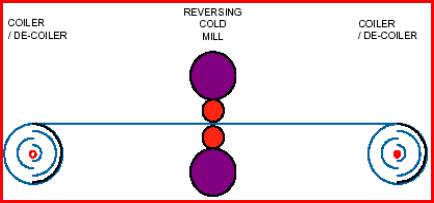

Figure : Cold-rolling principle

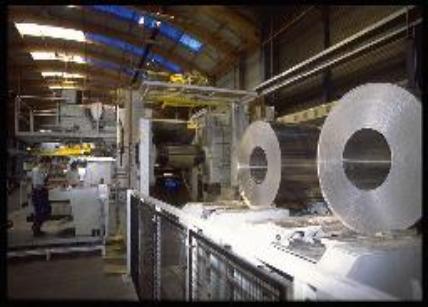

The strip from the hot

rolling mill is coiled for transport to the cold mill which might be on the

same site or elsewhere. Cold mills, in a wide range of types and sizes are

available; some are single stand, others 3 stands and some 5 stand (Figure). Cold rolling speeds vary but modern mills operate

at exit speeds as high as 3000 m per minute

and alloys may be cold rolled to thickness of around 0.05 mm

The strip from the hot

rolling mill is coiled for transport to the cold mill which might be on the

same site or elsewhere. Cold mills, in a wide range of types and sizes are

available; some are single stand, others 3 stands and some 5 stand (Figure). Cold rolling speeds vary but modern mills operate

at exit speeds as high as 3000 m per minute

and alloys may be cold rolled to thickness of around 0.05 mm

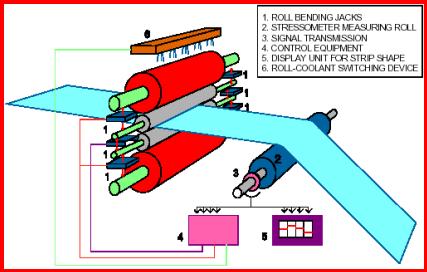

Figure :

Automatic flatness control system

(Source:European Aluminium Association

-niżej)

In many modern

installations concerned with the high volume production, for instance in the

canning industry, the very stringent flatness

requirements are achieved by combinations of mill control and by the

use of tension levellers (see Figure). Gauge control is achieved in much the

same way as flatness, i.e. by continuously measuring outgoing strip thickness

and adjusting the roll bite accordingly

In many modern

installations concerned with the high volume production, for instance in the

canning industry, the very stringent flatness

requirements are achieved by combinations of mill control and by the

use of tension levellers (see Figure). Gauge control is achieved in much the

same way as flatness, i.e. by continuously measuring outgoing strip thickness

and adjusting the roll bite accordingly

![]() The

Rolling of Aluminium: the Process and the Product

The

Rolling of Aluminium: the Process and the Product

prepared by Roy Woodward, Aluminium

Federation, Birmingham (24 pages, 29 figure)

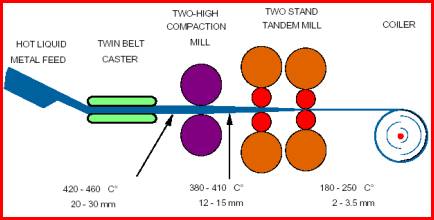

Continuous Strip Casting

Line

![]() Walcarki do gorącego

walcowania blach – SMS DEMAG

Walcarki do gorącego

walcowania blach – SMS DEMAG

![]() Walcarki do zimnego walcowania

blach – SMS DEMAG

Walcarki do zimnego walcowania

blach – SMS DEMAG

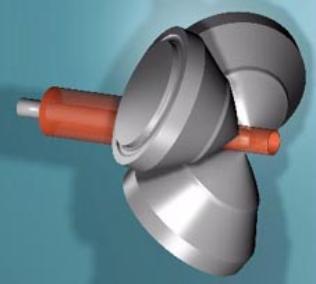

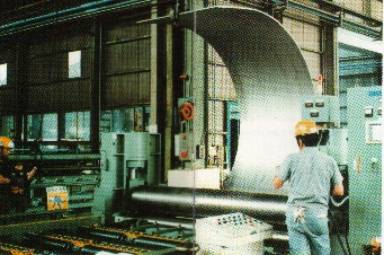

![]() Walcowanie rur z miedzi –

SMS DEMAG

Walcowanie rur z miedzi –

SMS DEMAG

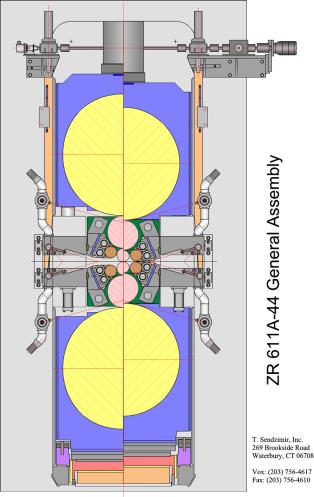

http://www.sendzimir.com/ What Role for the Z-High®

in Aluminium Mills?

http://www.sendzimir.com/ What Role for the Z-High®

in Aluminium Mills?

http://www.sendzimir.com/Papers/WhatRoleforZH/what_role_for_the_z.htm

![]() Pierwsza walcarka Sendzimira wybudowana w Polsce w roku 1932 (i inne procesy walcowania):

Pierwsza walcarka Sendzimira wybudowana w Polsce w roku 1932 (i inne procesy walcowania):

http://www.sendzimir.com/Papers/QualDev/Qualitydevelopment.pdf

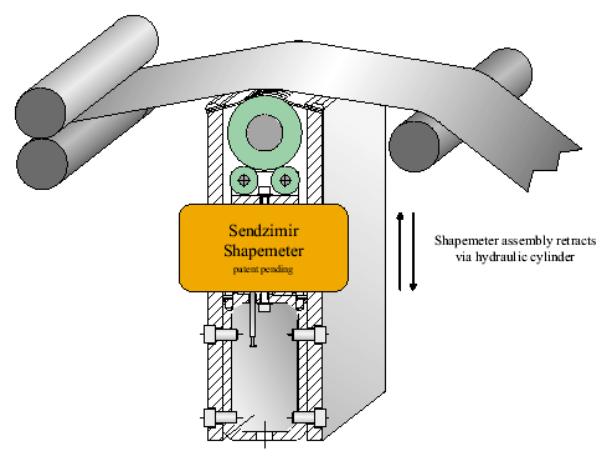

![]() Sendzimir's

New Shapemeter: web text or pdf text

Sendzimir's

New Shapemeter: web text or pdf text

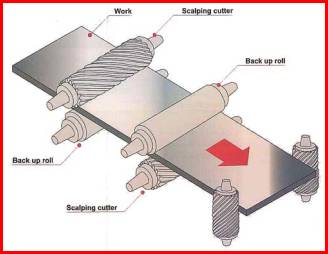

![]() CAST

AND ROLL™ Tube Process (miedzi) Cast and Roll line; Continuous

Casting; Planetary Rolling

CAST

AND ROLL™ Tube Process (miedzi) Cast and Roll line; Continuous

Casting; Planetary Rolling

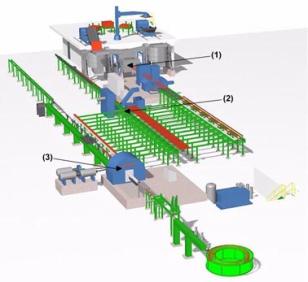

(1) Melting

and Casting area (2) Surface Milling area (3) Tube Rolling area

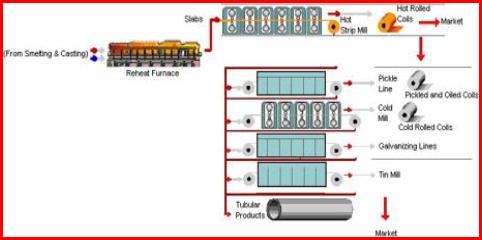

![]() Processes - Aluminum Casting &

Fabrication

Processes - Aluminum Casting &

Fabrication

![]() http://www.matter.org.uk/steelmatter/default.htm :

http://www.matter.org.uk/steelmatter/default.htm :

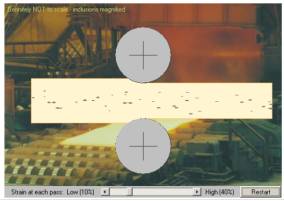

1) ![]() Elongation

of inclusions in hot rolling, 2)

Elongation

of inclusions in hot rolling, 2)

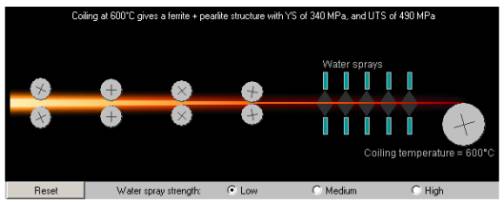

![]() Hot

rolling strip steels,

Hot

rolling strip steels,

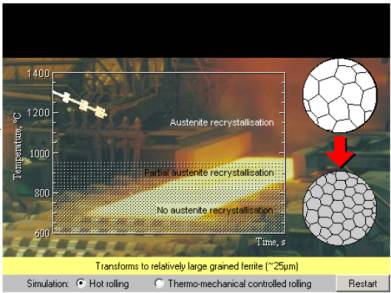

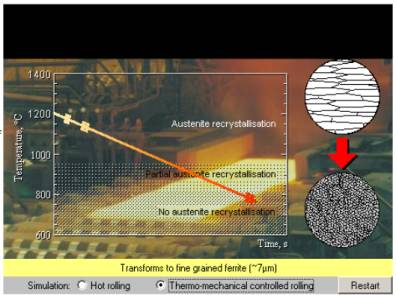

3)

![]() Control

of grain size through controlled rolling

Control

of grain size through controlled rolling

![]()

![]() Różne

sposoby otrzymywania walcowanych wyrobów: Hx, Tx – aluMAT (animacyjne

rysunki, 5 stron)

Różne

sposoby otrzymywania walcowanych wyrobów: Hx, Tx – aluMAT (animacyjne

rysunki, 5 stron)

![]()

![]() Procesy

walcowania na gorąco i zimno – aluMAT (animacja)

Procesy

walcowania na gorąco i zimno – aluMAT (animacja)

![]() Zastosowanie

stopów Al w procesach walcowniczych – aluMAT (gatunki)

Zastosowanie

stopów Al w procesach walcowniczych – aluMAT (gatunki)

![]()

![]() Procesy

walcowania, wyciskania ...- aluMAT (animacyjne rysunki)

Procesy

walcowania, wyciskania ...- aluMAT (animacyjne rysunki)

![]() CHICAGO METAL ROLLED PRODUCTS

(lepiej KLIKNĄĆ na

łącze podane niżej:

CHICAGO METAL ROLLED PRODUCTS

(lepiej KLIKNĄĆ na

łącze podane niżej:

- rodzaje kształtowników

walcowanych - 3 przycisk),

- ![]() animcja dwóch procesów gięcia

kształtowników – 4 przycisk:

animcja dwóch procesów gięcia

kształtowników – 4 przycisk:

![]()

![]() http://www.cmrp.com/cmrp/movie.html

http://www.cmrp.com/cmrp/movie.html

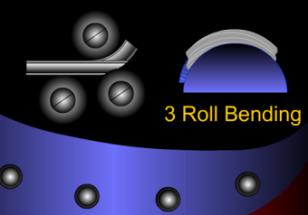

Bending

Roll / NC Bending Roll

Narzędzia

walcownicze - WALCE

is the facing cutter of brazed type and it is used to continuously rough up and down side of thin board of Copper and Copper alloy, rolled roughly in hot situation.

![]() Zastosowanie

blach aluminiowych na pokrycia dachowe

Zastosowanie

blach aluminiowych na pokrycia dachowe

Aluminium sheet used for roofing

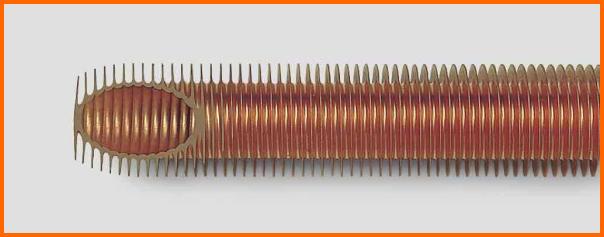

Walcowanie

specjalne:

Walcowanie

rur żebrowanych

![]() Walcowane rury żebrowane

BIP49_AGH

Walcowane rury żebrowane

BIP49_AGH

TECHNOLOGY TRANSFER PROGRAM:

![]() Mono and bimetallic

finned tubes produced in cold rolling process (technologia

AGH)

Mono and bimetallic

finned tubes produced in cold rolling process (technologia

AGH)

![]() Rury żebrowane - Wieland Internet

>Produkte>ROHRBEREICH>

Rury żebrowane - Wieland Internet

>Produkte>ROHRBEREICH>

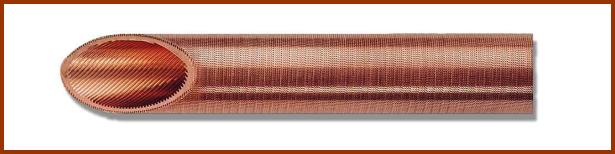

![]() Walcowane

rury żebrowane (gewalzte Rippenrohre – WIELAND)

Walcowane

rury żebrowane (gewalzte Rippenrohre – WIELAND)

![]() Rury

żebrowane chłodnicze i klimatyzacyjne

Rury

żebrowane chłodnicze i klimatyzacyjne

(für die Kälte- und

Klimatechnik – WIELAND)

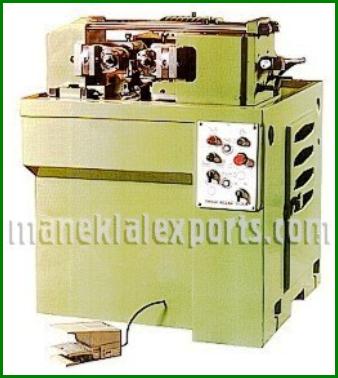

Form & Thread Rolling Machines

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

Home |

Aktualizowano:

2003-04-07