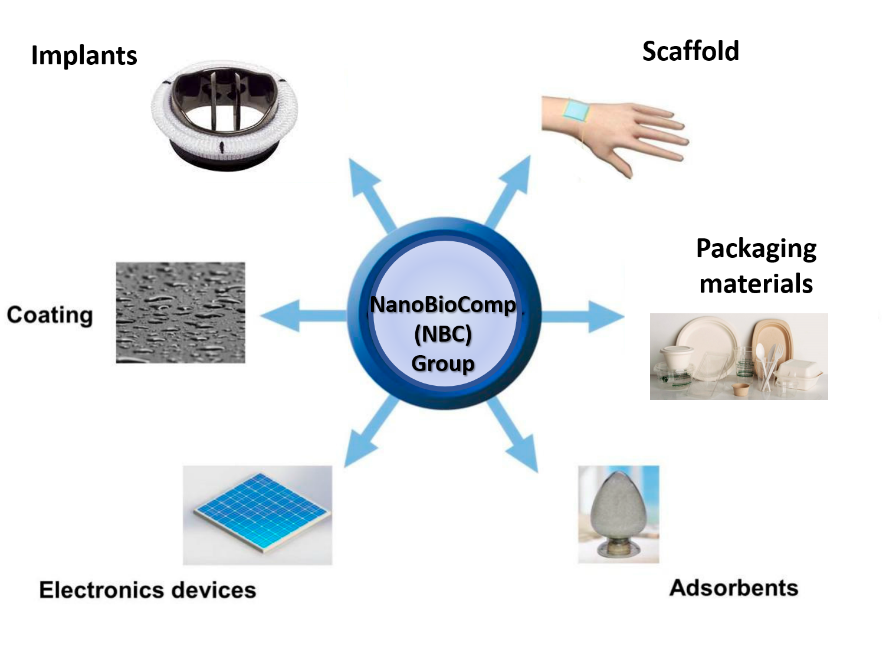

The aim of our research group is to develop nanocomposite materials dedicated to work both in biological environments (ie. living organisms) and as novel materials for technology and industry. Our group focuses on applying materials engineering to design, manufacture and test materials based on polymers modified with ceramic, carbon and/or natural nanoparticles (e.g. biological particles, natural and synthetic fibers, other natural additives).

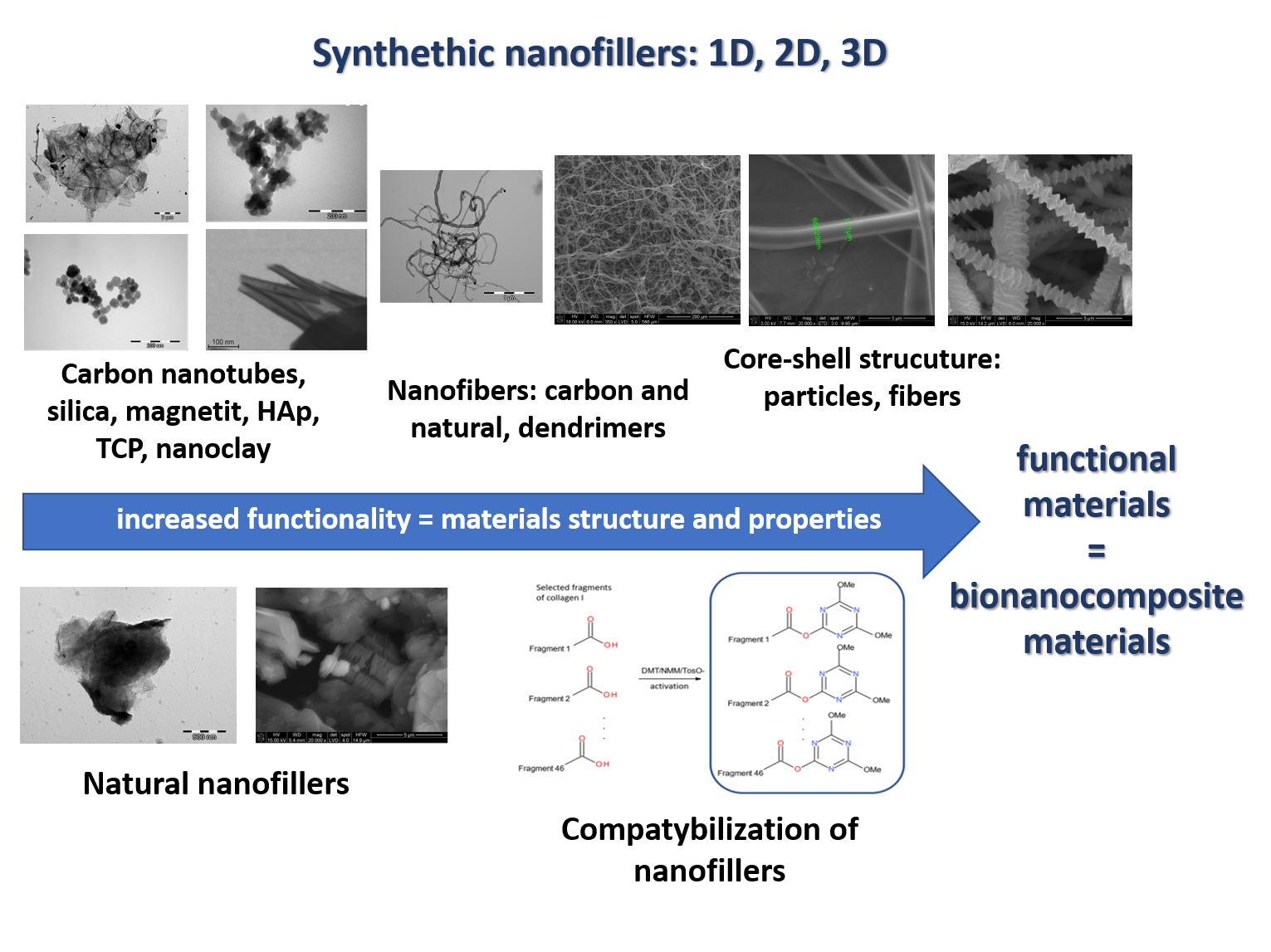

In order to meet high requirements concerning nanocomposites several methods are employed, such as chemical synthesis, chemical and physical modification of polymer matrices. A variety of specialized techniques are used (e.g. electrospinning, freezing drying, electrospraying or electrophoretic deposition (EPD), chemical vapor deposition (CVD)) to obtain materials with a sophisticated microstructure in terms of both volume and surface. Nanocomposites are also obtained via conventional methods based on polymer processing (injection, extrusion, lamination, casting, phase inversion). The work focuses on preparing fillers, ensuring their compatibility with the matrix and selecting optimal conditions for homogenization. We produce layered nanocomposites: 1D, 2D, 3D and MD, but also systems with the dispersive arrangement of the filler. The obtained materials can be used in the following areas:

- Biomaterials engineering; medicine and veterinary medicine

- Biomedical engineering; sensors, electrode coatings

- Chemical technology; thermal energy storage materials

- Electronics; energy storage, semiconductor technologies

- Environmental protection; water desalination

- Eco-materials; biodegradable materials, packaging, fast-moving consumer goods

- Membrane: base on-polymer, composite and nanocomposite membrane

Carbon materials are particularly worthy of interest. The synthesis and modification of carbon nanotubes (CNTs), graphene or carbon nanofibers (CNFs) serve their purpose in the following scientific areas: energy storage techniques, water purification and desalination, supercapacitors, new materials solutions in electrochemistry, improvement of the biocompatibility and biofunctionality of biomedical materials, with particular emphasis on medical implants. A number of (nano)composite solutions are used to produce environmentally friendly packaging (eco-materials). Natural components, e.g. nanometric clays (kaolin, montmorillonite), natural fibers (flax, hemp, bamboo) or (nano) cellulose, are the basis for designing new, fully degradable packaging. Inorganic and organic additives affect the flammable properties of polymers, which is also one of our interests.