Netzsch LFA 457 Microflash

This device allows for measurement of thermal diffusivity (accuracy ±3%, range: 0.01 – 1000 mm2/s) and specific heat (accuracy ±5%) of materials from -125°C to 1100°C.

Netzsch DSC 404 F3 Pegasus

This device (High-Temperature Differential Scanning Calorimeter) can operate from -150°C to 1100°C with various DTA and DSC sensors. The sample chamber can be purged with inert (Ar) or oxidizing gases in order to remove gases evolved from the sample.

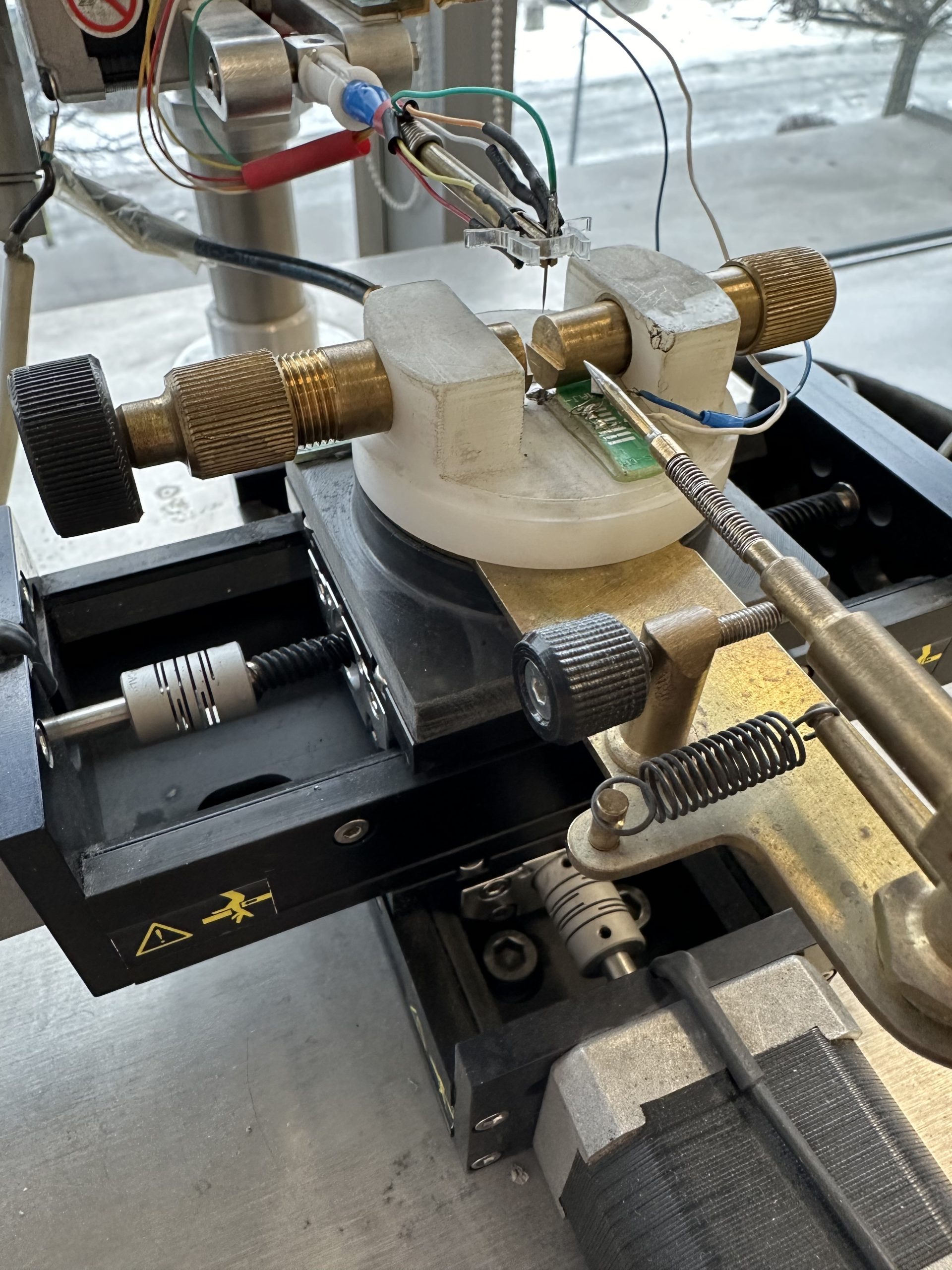

Scanning Thermoelectric Microprobe (STM) Apparatus

This device allows for localized measurement of the Seebeck coefficient (S) and electrical conductivity (σ) on the surface of samples. Mapping of S involves measurement of the voltage between the heated measuring electrode and reference at different points on the sample’s surface.

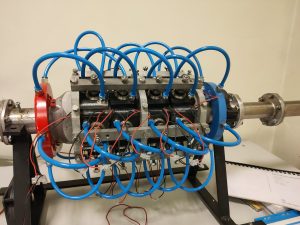

Linseis Hall characterization system HCS 1

The HCS 1 provides measurements of Hall mobility, carrier concentration, resistivity and Seebeck coefficient over the temperature range of LN2-600 oC. Characterization can be performed on bulk or thin film samples. The sample chamber can be purged with inert (Ar) or oxidizing gases to remove evolved gases from the sample. The HCS 1 stage is equipped with two permanent magnets (neodymium, 0.70 T) assembled on a movable sledge.

Devices for material processing

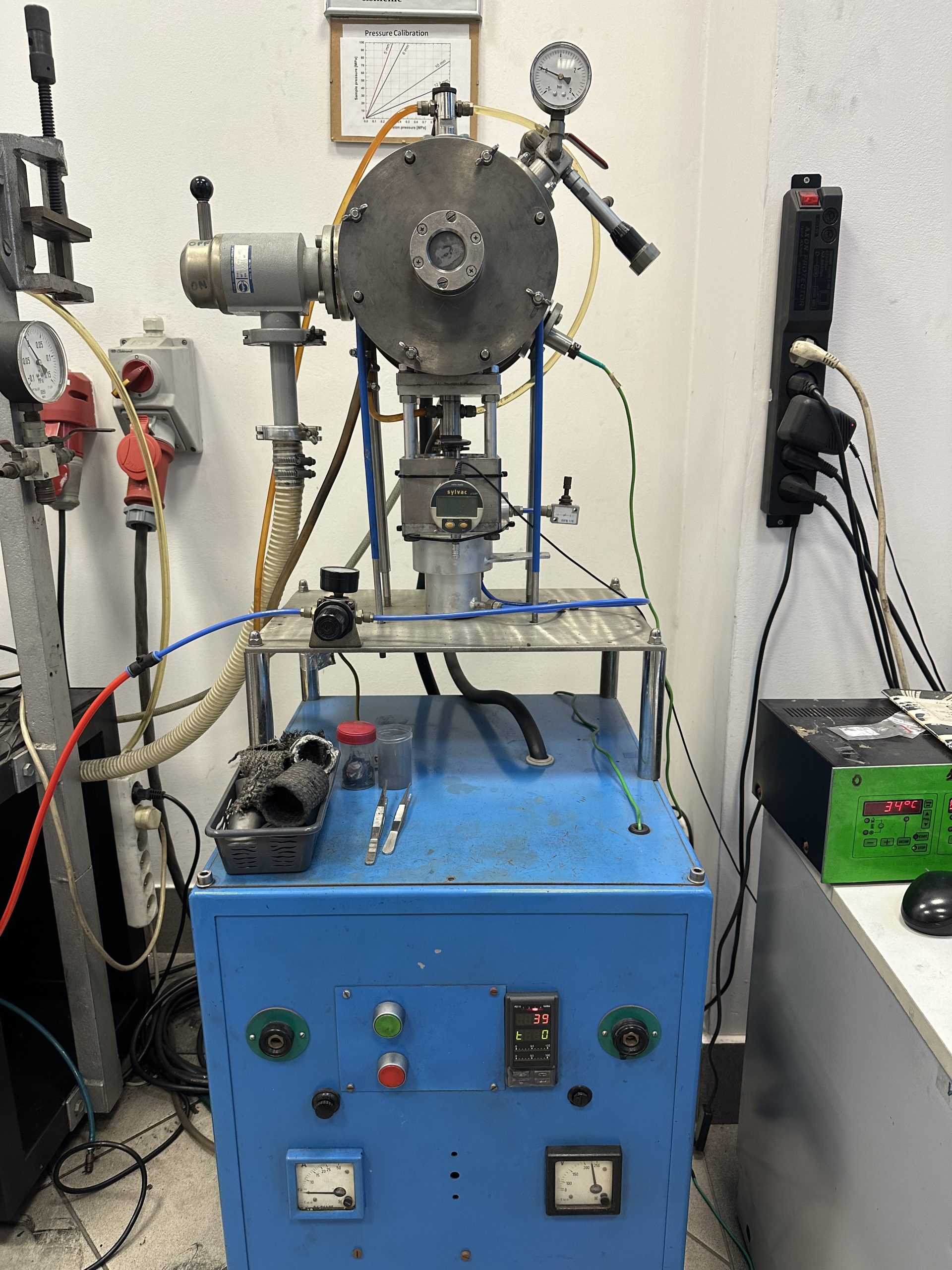

Pulsed Electric Current Sintering (PECS)

This device allows for consolidation of powders in graphite matrices. Maximum available working temperature and pressure are 1000 °C and 60 MPa (depending on matrix). Air or inert gas atmosphere (Ar) are available.

Magnetron

This device allows us for deposition of thermoelectric thin films, thin interdiffusion barriers and contact layers for thermoelectric elements.

Anodizing line

This line makes it possible to fabricate a stable Al2O3 dielectric coating on the surface of the aluminum electrode. The line consists of 7 bathtubs in which the processes of cleaning and degreasing aluminum plates are first carried out followed by the anodizing process itself. It is possible to turn on mixing in every bathtub. The anodizing process is made in an aqueous solution of sulfuric acid with a lead cathode.

Thermoelectric generators

Solar Thermoelectric Generator

This device is designed to convert thermal energy from solar radiation into electricity. Thermoelectric energy conversion is performed by thermoelectric modules using the absorbing plate with high emissivity coating to collect solar energy more efficiently. The presented STEG prototype can be effectively used as a reliable source of electric energy in hot desert climates and excessive sunlight areas.

Thermoelectric Generator Testing Apparatus

This device allows for estimation of the efficiency of the generator in various working conditions. Modules are mounted onto a designed heat exchanger connected to hot air blower (air temperature up to 500 °C) and water cooling system with independent cooling unit equiped with temperature control.