Materiały KOMPOZYTowe Część I ^

Materiały KOMPOZYTowe Część II ^

Materiały KOMPOZYTowe Część III ^

![]() .

.

4. Materiały gradientowe

Część IV

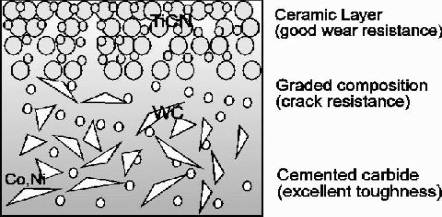

![]() Graded Tribological Materials:

Graded Tribological Materials:

![]() Publikacje o materiałach gradientowych Functionally

Gradient Materials (Lista 5. publikacji)

Publikacje o materiałach gradientowych Functionally

Gradient Materials (Lista 5. publikacji)

![]() Gradient Alumina-Aluminide Alloys (3A):

Gradient Alumina-Aluminide Alloys (3A):

1)

dry-pressing > Graded

3A-Materials made by dry-pressing of the precursor powder:

30 vol.% Ti-aluminide/20 vol.% Ti-aluminide/10 vol.% Ti-aluminide

2)

dip-coating > Graded

3A-Materials made by dip-coating of a porous alumina:

Functionally Graded Al2O3-Aluminide

Materials

30 vol.% Fe-aluminide/ 20 vol.% Fe-aluminide/ 10 vol.% Fe-aluminide

3)

slip-casting > Graded 3A-Materials made by

slip-casting:

Determination of a casting technique for the production of

metallic materials with gradient structure-Aachen:

Determination of a casting technique for the production of

metallic materials with gradient structure-Aachen:

Fig. 1:

Cast structure with a continuous Si-concentration gradient between the plate

and trapezoid

![]() TECHNOLOGIE WARSTW WIERZCHNICH (powłoki

warstwowe i gradientowe)–RADOM:

TECHNOLOGIE WARSTW WIERZCHNICH (powłoki

warstwowe i gradientowe)–RADOM:

|

|

powłoki proste: TiN, CrN, ZrN, |

|

|

powłoki złożone: wieloskładnikowe - Ti(C,N), (Ti,Al)N, (Ti,Zr)N,

(Ti,Cr)N, |

|

|

wielowarstwowe i gradientowe – TiN/Ti(CxN1-x) |

Interfaces between metals/ceramics: high power lasers:

Interfaces between metals/ceramics: high power lasers:

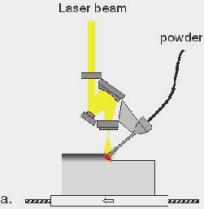

Surface

composite and functionally gradient materials

with lasers,Y.T.

Pei,J.Th.M. De Hosson

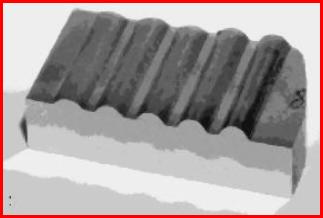

Laser cladding of FGCs with dynamic

powder feeding technology (a) and the sample of single track FGCs (b).

![]() Laser-Powder Cladding - JOM (Y.T. PeiJ.Th.M. De Hosson, Producing Functionally Graded Coatings by Laser-Powder Cladding,

JOM, 52 (1) (2000)

Laser-Powder Cladding - JOM (Y.T. PeiJ.Th.M. De Hosson, Producing Functionally Graded Coatings by Laser-Powder Cladding,

JOM, 52 (1) (2000)

The term "functionally graded materials"

(FGMs) is now widely used by the materials

community for a class of materials exhibiting spatially inhomogeneous

microstructures and properties.

The top (a) intermediate (b), and bottom (c) of a graded

microstructure of Al-40Si FGC produced at 3,000

W laser power and 26.7 mm/s beam speed. The arrows indicate five-branch silicon

particles.

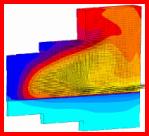

The temperature field of the laser pool in the case of

cladding Al-40Si FGCs. Isotherms I1 and I2 represent the liquidus

of Al-40Si alloy and the Al/Si eutectic

temperature, respectively; Vb is the beam scanning speed; and Vs is the speed of eutectic growth front.

The hardness distribution of laser-clad Al-40Si FGCs produced with different powder feeding rates ^

![]()

Materiały KOMPOZYTowe Część I ^

Materiały KOMPOZYTowe Część II ^

Materiały KOMPOZYTowe Część III ^

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Aktualizowano:

2003-04-16