Materiały KOMPOZYTowe Część II >

Materiały KOMPOZYTowe Część III >

Materiały gradientowe Część IV >

![]()

1.

Materiały

KOMPOZYTowe

Część I

Uwaga dotycząca studentów: Rok IV PP: „Technika Wytwarzania

Kompozytów Metalowych” (przedmiot wybieralny). W celu ułatwienia wykonania indywidualnych opracowań

do niniejszej

strony internetowej wprowadzono polską terminologię:

|

General Definitions Ogólne

definicje |

Reinforcement Faza zbrojąca |

Types of MMC Rodzaje kompozytów metalowych |

|

·

Composite

(kompozyt =osnowa+faza zbrojąca) ·

Hybrid

Composite (kompozyty hybrydowe) ·

Ingredient

Materials (składniki materiałowe, komponenty) ·

Interface

(strefa wzajemnego oddziaływania) ·

Metal

Matrix (osnowa metalowa) ·

Metal

Matrix Composite (kompozyty metalowe =osnowa metalowa+faza zbrojąca) ) ·

Reinforcement (faza zbrojąca) |

·

Continuous

Fibres (włókna ciągłe) ·

Continuous

Reinforcement (zbrojenie ciągłe) ·

Discontinuous

Reinforcement (zbrojenie nieciągłe) ·

Dispersoids

(cząsteczkowa faza zbrojąca) ·

Monofilaments

(włókna pojedyncze) ·

Platelets

(płytki) ·

Short

Fibres (krótkie włókna) ·

Whiskers

(whiskersy) |

·

Cellular

Metals (Foams)

(metale komórkowe - pianki) ·

Cermets

(cermety) ·

Continuous

Reinforced MMC (kompozyty metalowe zbrojone włóknami

ciągłymi) ·

Dispersoid

Reinforced MMC

(kompozyty metalowe zbrojone dysprsyjnie) ·

MMC

Designation (oznaczenie metalowych kompozytów) ·

Monofilament

Reinforced MMC

(kompozyty mtalowe zbrojone pojedynczymi

włóknami) ·

Particulate

Reinforced MMC

(kompozyty metalowe zbrojone cząsteczkami) ·

Short

Fibre Reinforced MMC

(kompozyty metalowe zbrojone włóknami krótkimi) ·

Whisker

Reinforced MMC (kompozyty metalowe zbrojone

whiskersami) |

|

General Definitions Ogólne

definicje Composite: A composite (or composite material) is

defined as a material that consists of at least two constituents (distinct

phases or combinations of phases) which are bonded together along the

interface in the composite, each of which originates from a separate

ingredient material which pre-exists the composite. The essential elements of this definition are :

i.

composite refers to a material, as opposed to a

structure or a component; as such a composite material is used for the

fabrication of components of various shapes or functions, thus it should be

distinguished from a wing or other structure made of several components

bonded together, and from an electronic device or packaging structure made of

layered materials (although one of the materials in the packaging could be

considered a composite);

ii.

the

composite is produced via a physical combination of at least two pre-existing ingredient materials; this distinguishes a composite from other

multiphase materials which are produced by bulk processes where one or more

phases result from phase transformation: many "in-situ composites",

such as directionally solidified eutectics or alloys from which a ceramic

phase is precipitated, are thus considered to be alloys and not composites

(even though their properties can be described using composite theory). Hybrid composite (kompozyty hybrydowe): a composite that consists of at least three (as

opposed to two) constituents (distinct phases or combinations of phases)

which are bonded together at the atomic level in the composite, each of which

originates from a separate ingredient material which pre-exists the composite

(i.e., there are, at least three ingredient materials) >kompozyty zbudowane z trzech lub więcej składników (tworzących odmienne

fazy lub kombinacje fazowe), które pochodzą z różnych materiałów (dwie osnowy

lub więcej faz zbrojących). Ingredient materials (składniki materiałowe): Raw materials put together to produce the composite

(e.g., the metal alloy, metal powder, ceramic particles, etc.). During the

processing the ingredient materials are transformed into the constituents of

the MMC. Interface (strefa wzajemnego oddziaływania): that portion of the composite microstructure that

lies between its constituents, i.e. matrix and reinforcement. The interface

may be a simple row of atomic bonds (e.g., the interface between alumina and

pure aluminium), but may also include matrix/reinforcement reaction products

(e.g., aluminium carbide between aluminium and carbon fibres), or

reinforcement coatings (e.g., interfacial coatings between SiC monofilaments

and titanium matrices). Metal matrix (osnowa metalowa): the percolating metal or alloy forming the

constituent of a MMC in which the other constituents are embedded. Metal Matrix Composite (MMC) (kompozyty metalowe): a composite material in which one constituent is a

metal or alloy forming at least one percolating network. The other

constituent is embedded in this metal matrix and usually serves as

reinforcement. Reinforcement (faza zbrojąca): a constituent (phase or combination of phases) of

the MMC originating from the ingredient material which is combined with a

metal or an alloy to produce a metal matrix composite (e.g., alumina fibres,

silicon carbide whiskers, steel fibres, or graphite particles, even if, in the

case of graphite particles, the reinforcement does not "reinforce"

the matrix). A reinforcement is characterised by its chemical composition,

its shape and dimensions, its properties as ingredient material and its volume fraction and spatial distribution in the

matrix. |

|

Reinforcement Faza zbrojąca Continuous fibres (f) (włókna ciągłe): cylindrical ingredient material produced

continuously to form an essentially endless reinforcement in the composite; usually

delivered on bobbins of multifilament tows, each tow consisting of many

individual fibres of diameters typically in the range of 3 to 30 µm.

According to the production process such fibres are usually coated by a

polymeric sizing and the tows may be slightly twisted. They are typically

designated by a brand name, the number of fibres per tow and a symbol of the

applied sizing (e.g. T300-6K-E). Continuous reinforcement (zbrojenie ciągłe): a constituent of a composite which is continuous in

at least one direction through the composite (e.g., continuous fibres or

percolating open-celled foam). Discontinuous reinforcement (zbrojenie nieciągłe): a non-percolating constituent of a composite,

taking the form of individual elements embedded in the matrix constituent

(e.g., particulates, short fibres, whiskers). Preforms produced from

discontinuous reinforcements that are mechanically stabilised by a binder or

by cold compaction are still considered discontinuous reinforcements. Dispersoids (d) (cząsteczkowa faza zbrojąca): same as particulates, except that the diameter is

less than 1µm, hence, being capable of providing Orowan strengthening. Monofilaments (m) (włókna pojedyncze ciągłe): essentially endless reinforcement as continuous

fibres, except for a larger diameter, typically greater than 100 µm.

Monofilaments are generally produced by deposition onto a core fibre (most

often of carbon or tungsten), and are delivered as individual fibres instead of tows (zamiast wiązki włókien). Particulates (p) (cząstki): roughly equiaxed

reinforcement or composite ingredient, usually of aspect ratio (ratio of

largest to smallest diameter) less than about 5. Particulates can be both

mono- or polycrystalline, can take various shapes (spherical, angular,

plate-like) and are typically greater than 1 µm in diameter. Platelets (płytki): flat reinforcements of an aspect ratio

(diameter to thickness) greater than 2. Platelets of an aspect ratio less

than 5 can be considered as a type of particulates. Short fibres (s) (krótkie włókna): cylindrical reinforcement or composite ingredient

with a ratio of length to diameter greater than 5 (but typically greater than

100), and with a diameter typically greater than 1 µm. Whiskers (w) (whiskersy): elongated single crystals,

typically produced with a length to diameter ratio greater than 10 and with a

diameter typically less than 1µm. |

|

Types of MMC (Metal Matrix Composite) Rodzaje kompozytów metalowych Cellular metals (metal foams) (metale komórkowe – pianki metalowe): similar to MMC as they are often formed by

combining two separate ingredients yielding a metal matrix and the second

constituent being the gas in closed or open pores: however, there is no clear

bond between the gas phase and the matrix. Cermets (cermety): a metal matrix composite with a three-dimensionally

percolating ceramic reinforcement, typically with far more ceramic than metal

(generally containing less than 20% metal by volume). According to the

percolating structure of both constituents cermets can thus be considered as

both a ceramic and a metal matrix composite. Continuous fibre reinforced MMC (CFRM) (kompozyty metalowe zbrojone włóknami ciągłymi): metal matrix composite with reinforcement of

continuous fibres.

Dispersoid reinforced MMC (kompozyty metalowe zbrojone dyspersyjnie): metal matrix composite with a dispersoid

reinforcement occupying a volume fraction greater than 5% in the material

(otherwise, the material is considered to be a dispersion strengthened metal

- which incidentally may form the matrix of any type of MMC, i.e., a MMC with

dispersion-strengthened matrix). MMC (Metal Matrix Composite) designation (oznaczenie metalowych kompozytów): method of indicating the composition and at times also

the processing of the MMC. As proposed by the American Aluminum Association

for the designation of aluminium composites, MMC should be designated as

follows by their constituents: accepted designation of the matrix / abbreviation of

the reinforcement’s designation / arrangement and volume fraction in % with

symbol of type (shape) of reinforcement. Some examples are: matrix of a magnesium alloy AM10

reinforced by continuous carbon fibres of type T300, unidirectionally

oriented, amounting to a volume fraction of 65% is designated as

"AM10/C-T300/UD65 f"; or matrix of the aluminium alloy AA6061 reinforced

by particulates of alumina of 22 % by volume is designated as

"AA6061/Al2O3/22 p". MMC product names used by companies vary, hence

their use indicates the processing route employed by implicit reference to

the producer. Monofilament reinforced MMC (MFRM) (kompozyty mtalowe zbrojone pojedynczymi włóknami): metal matrix composite with reinforcement of

monofilaments. 1) 1) Particulate reinforced MMC (PRM) (kompozyty metalowe zbrojone cząsteczkami): metal matrix composite with a particulate

reinforcement occupying a volume fraction greater than 5% in the material

(otherwise, the particulates are generally considered to be inclusions). 2) Short fibre reinforced MMC (SFRM) (kompozyty metalowe zbrojone włóknami krótkimi): metal matrix composite with a short fibre

reinforcement. 3) Whisker reinforced MMC (WRM) (kompozyty metalowe zbrojone whiskersami): metal matrix composite with a whisker reinforcement |

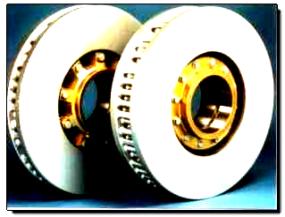

Brake

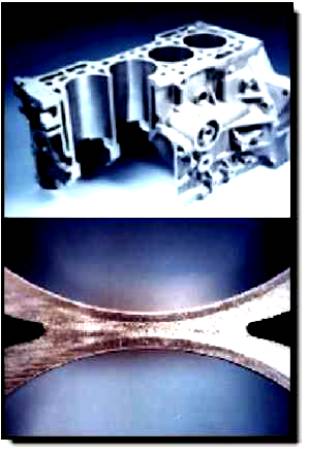

rotors for German high speed train ICE-2 Cylinder liner

1) 2)

2)

1) Brake rotors for German high speed train ICE-2

made from a particulate

reinforced Aluminium alloy (AlSi7Mg+SiC particulates, supplied by Duralcan), developed by Knorr Bremse AG

2) The Kolbenschmidt AG in cooperation with the Porsche AG has

developed the LOKASIL-composite technique. It is in use as cylinder liner in the Porsche Boxter engine

block: the cylinder liner is made

by selectively

reinforcing the crank case, consisting

of AlSi9Cu3 alloy. The selectively reinforced parts are produced with

preforms containing 25% Si (made by CeramTec), in combination with the squeeze casting technique.

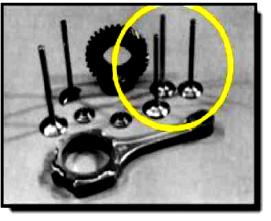

Ti-MMC Exhaust Valves / Toyota Altezza MMC

Brake Rotors or Brake Drums Forged

Connecting Rod

^Discontinuously reinforced

Ti-Alloy: high temperature wear resistance

MMC Cylinder Liners / Honda Prelude:

-

Al/Al2O3-Graphite DRA 12% Al2O3 for Wear 9% Graphite for Lubricity-

Integrally Cast With Al-Engine Block- Improved Wear

F–16 Ventral Fins: 6092/SiC/17.5p rolled P/M produced by DWA Composites previous

material was 2024-T4 Al

F–16 Ventral Fins: 6092/SiC/17.5p rolled P/M produced by DWA Composites previous

material was 2024-T4 Al

< F-16 Fuel Access Door

Covers

< F-16 Fuel Access Door

Covers

MATERIAL: 6092/SiC/17.5p wrought P/M material

produced by DWA Al Composites, Inc. DRA replaced 2024 Al doors

BENEFITS: 38% lower peak skin stresses, ~10%

reduction in average skin stresses, 28% increase in bearing allowable over 2024

Al; elimination of the skin cracking problem

![]()

Materiały KOMPOZYTowe Część II >

Materiały KOMPOZYTowe Część III >

Materiały gradientowe Część IV >

Aktualizowano: 2003-04-16